The technology of assembly and handling plays (s.o.) a key role in industrial production. It is practically the pacemaker of modern and flexible manufacturing and production technologies. Classic fields such as engineering and vehicle construction, logistics or micro technology are within the extremely ample spectrum of users. However, branches such as medicine, food or photovoltaics are also increasingly becoming potential users, not to forget service robotics for cleaning, surveillance, rehabilitation or also entertainment.

Robots are gaining ground

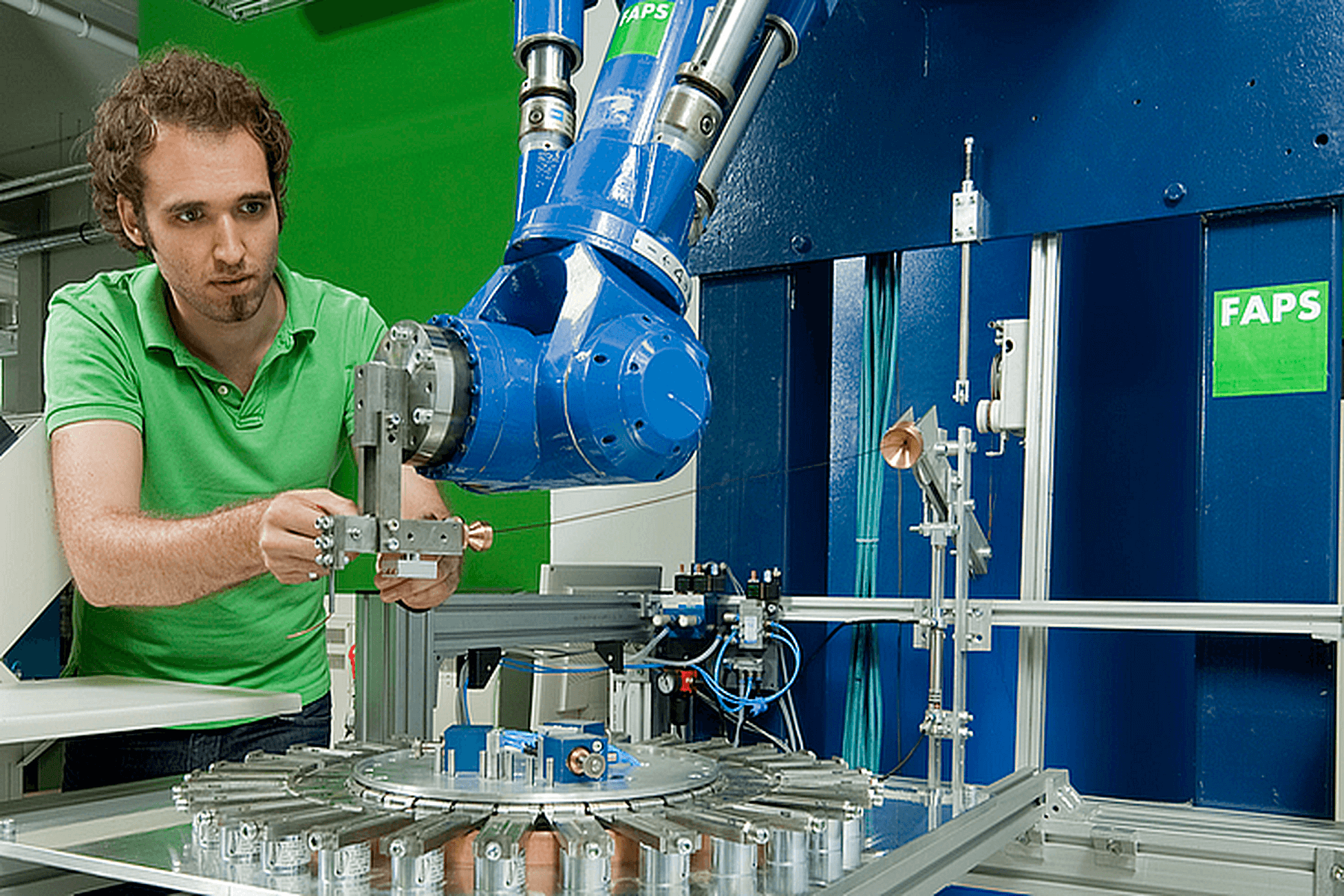

The term assembly refers to all operations that help to assemble products. At this, the handling and joining of single components are important partial processes. Essential elements for the automation of assembly are industrial robots. According to VDI norm 2860, they are freely programmable concerning movement sequence and distances resp. angles as universally applicable moving machines with several axes. Compared with their predecessors 30 years ago, robots can carry much heavier loads, have become considerably faster at the same time and work much more precisely. This development is owed to progress in the fields of gears, sensors and robot control technology. And it is the basis for ever increasing degrees of automation in the most diverse applications such as body construction. At the same time, the systems are becoming more cost-effective and, thus, more attractive for automation.

Machines with cognitive abilities

Robotersysteme zur automatisierten Handhabung sind in den vergangenen Jahren insIn the last years, robot systems for automated handling have become much more efficient and adaptable, especially due to the integration of sensor systems such as cameras and force/momentum sensors. However, researchers have set themselves a far higher goal. They are trying to transfer the human’s cognitive abilities to robots and first successes have been scored. For example, robots are automatedly teachable concerning complex gripping processes. This, in turn, makes applications imaginable, when handling pliable materials in automotive assembly, among others. The well-known “bin picking” is also benefitting from the artificial intelligence of machines.

“Soft“ robots are becoming even more flexible

Researchers are working on the simplification of robot programming so as to make the use of robots easier for small and medium-sized companies as well. This simplifies the handling of these machines for specialist workers.

So-called soft robotics represent another innovative and promising approach. At this, robots – especially grippers – are made safer and, at the same time, more mobile on the basis of soft structures. Soft robotics subsist on the use of new materials, additive manufacturing processes and new drive concepts. However, basic further developments in control and regulation techniques are still necessary first of all. Only then will robots be able to reproduce the enormous flexibility of the human hand, for example, for assembly and handling operations.

Flexible robot integration in the sense of “plug & produce“ is becoming increasingly easier not least because of digitalization and networking. In connection with driverless transport systems and mobile robot platforms, the first highly-flexible assembly lines are showing up in industry, thus dissolving the rigid connection between belt and cycle.

Robots support customized production

The development of flexible automated systems for assembly and handling is becoming all the more important due to the trend towards customized production. At this, it has become obvious that the close collaboration between human and robot holds special potentials. Since it is in the human-robot collaboration that the excellent cognitive and sensomotoric abilities of the human are ideally connected with the precision, speed and mechanic performance of the robot. Robot systems that, due to their design, integrated sensors, control technology and further measures, bear no danger for the humans working in close proximity are, however, the precondition for this.

In the fields of assembly and robotics, the WGP is cooperating closely with the Corporation for Assembly, Handling and Industrial Robotics (Wissenschaftliche Gesellschaft für Montage, Handhabung und Industrierobotik e.V. – www.wgmhi.de), which is focussed on this field.