Aachen / Hannover, December 16, 2021 – A new concept of an Update Factory shows an almost revolutionary way how manufacturing companies can develop innovative business models with industrial updates of their products. The position paper was created in collaboration between WGP (Scientific Society for Production Engineering) and WiGeP (Scientific Society for Product Development). “We have completely rethought sustainability. The Update Factory would be a big step towards the urgently needed circular economy,” emphasizes Prof. Volker Schulze, main author of WGP and spokesman of the Institute Management of the Institute of Production Engineering wbk at the Karlsruhe Institute of Technology (KIT). Prof. Frank Mantwill, main author of WiGeP and head of the Chair of Machine Elements and Computer Aided Product Development (MRP) at Helmut Schmidt University in Hamburg adds, “Germany is an important and leading production location. With the Update Factory, we can contribute as a role model to the achievement of climate protection goals and the implementation of the European Green Deal. It definitely has the disruptive potential to reshape value creation in an economically and ecologically sustainable way.”

Industry is responsible for a good fifth of total CO2 emissions in Germany. A lot is already happening in this sector to change that, but the Update Factory concept takes a completely new approach. The research team shows companies how they can increase the useful life of their products by selectively taking them back, refurbishing them, upgrading them and returning them. This requires new business models that add value for both the provider and the customer. Aging smartphones, for example, can be upgraded several times in an update factory and brought up to date with the latest technology and design. “To do this, however, the repeated upgrade must be considered from the outset, and production and product development must be brought together,” emphasizes Mantwill. “However, a lot still needs to be done for such co-design.”

Keeping production in Germany

Such “simultaneous engineering” requires close dovetailing of a wide variety of measures in the development of a product. For example, consideration of the entire product life cycle coupled with cross-generational development plays a crucial role in product development and must be combined with systems for automated findings, disassembly and reassembly in production. In this context, digital cloud-based condition monitoring of the product can trigger the update as a whole, but also the production of presumably required replacement parts.

“Manufacturers need to think in generations, and they need to reverse logistics, so to speak. In production, they then have to deal with highly changeable input states of products to be disassembled. By reengineering these products, however, they are helping to secure jobs in Germany as a production location, because the necessary know-how is only available here,” Schulze said.

Questions still open

However, the Update Factory concept still poses a number of challenges. For example, how can warranty be defined for the business models? How can the complete product life cycle be digitized? And last but not least: How can raw material, emission and energy consumption of the update products be evaluated and thus prove the advantages of the strategy in terms of sustainability? In their position paper, the scientists have set out twelve theses to define both the initial situation and the interdisciplinary need for research. The goal is to advance the research together with companies and other academic partners in order to achieve the climate goals of politics in terms of a circular economy, but also a competitive industry. “The Update Factory definitely has the disruptive potential to reshape value creation in an economically and ecologically sustainable way,” says Prof. Frank Mantwill, lead author of WiGeP and head of the Chair of Machine Elements and Computer-aided Product Development (MRP) at Helmut Schmidt University in Hamburg.

Download:

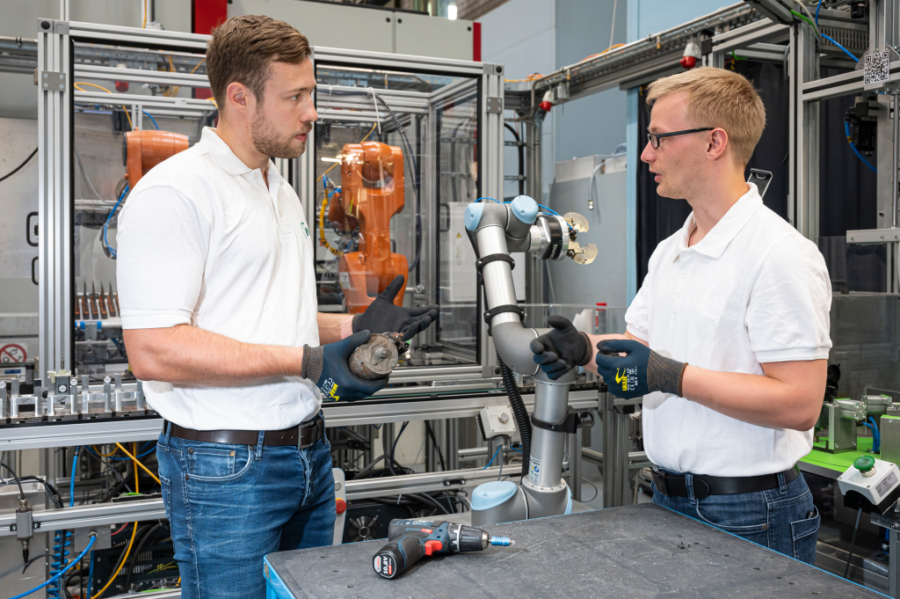

Cover image: Research in the field of remanufacturing as an enabler for the implementation of the Update-Fatory, Source: wbk Karlsruhe