Munich, 13 February 2024 – In times of digitalisation and rapidly developing new technologies, lifelong learning is a must – for engineers as well as for the men and women at the machines. Since February, companies have been able to bring their employees up to speed with the latest technology at the WGP Production Academy, whether it’s AI, electric drives, 3D printing or modern production planning. With its one- to two-day seminars, the Wissenschaftliche Gesellschaft für Produktionstechnik (WGP) aims to accelerate the transfer of knowledge from universities to industry, which all too often takes years. “By the time the knowledge has finally arrived in practice, it is often already outdated. With us, companies can bring their employees up to speed with the latest production technologies in a condensed format,” explains WGP President Prof Michael Zäh, who also heads the Institute for Machine Tools and Industrial Management (iwb) at the Technical University of Munich. “Our research is geared towards current challenges, such as energy efficiency and resilience. In this way, we can help small and medium-sized companies in particular to remain competitive with low to moderate financial and logistical outlay.”

At the WGP Production Academy, interested parties can find a wide range of topics, from practical production technology training to economic and organisational seminars. Its portfolio also includes the highly topical subject of artificial intelligence.

Intelligent shop floor management and resource efficiency

Discussions about AI mostly relate to the evaluation of sensor data. The valuable knowledge that exists within a company is not included here. However, AI can help to automatically summarise this implicit knowledge into a structured database. In addition, employees can be supported in shop floor meetings, for example by digital assistants in finding and eliminating deviations. In Darmstadt on 12 March 2024, interested parties will learn about best practices and carry out practical exercises.

In the Process, Tool and Machine Analysis seminar in Stuttgart, for example, interested parties will learn about the latest methods for the efficient use of machines and tools. After the two days in October, they will have numerous examination methods for analysing and designing machining processes at their disposal. With the help of these methods, employees can better utilise or exploit existing resources.

Programmes can also be booked digitally and in modules

The seminars take place at WGP institutes with the respective research focus, so that participants benefit from a high level of expertise and outstanding infrastructure. This also applies to the virtual training courses on forming technology offered by researchers from Stuttgart in May and November. In 60-minute digital teaching units, the experts convey the current state of the art in the individual forming processes as well as current trends in research and practice. The target groups for this newly prepared content are beginners, advanced students and professionals from sheet metal and solid forming as well as related fields. The units are categorised as “Beginner” or “Experts” in order to offer participants the greatest possible benefit for their day-to-day business.

A quality check of all seminars also guarantees the highest standards of content and implementation. At the end of the events, certificates attest to the cutting-edge knowledge. All training courses are also designed as modules that can be put together individually – an innovative WGP format for sustainable production.

Further information:

WGP Production Academy – all seminars and registration: https://wgp.de/de/produktionsakademie/

Download:

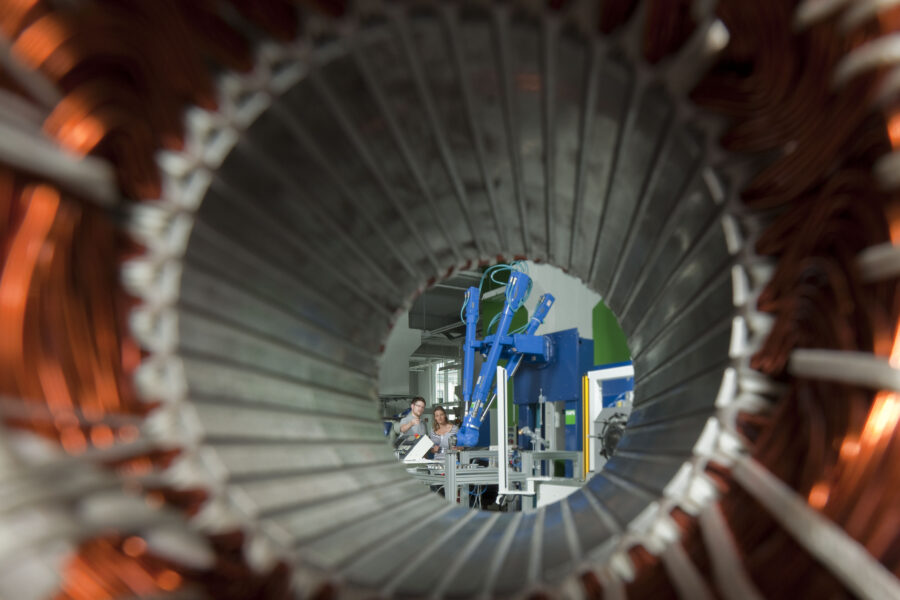

Image 1: View through the laminated core of a stator (seminar on the production of electric drives), source: FAPS Erlangen

Image 2: Prof Michael Zäh, WGP President and Head of the Institute for Machine Tools and Industrial Management (iwb) at the Technical University of Munich, source: iwb Munich, Sebastian Kissel